STC-9200 Temperature Controller

🎯 SEO OPTIMIZATION ELEMENTS

Focus Keyphrase (191 chars max)

“STC-9200 Digital Temperature Controller: Professional Refrigeration Thermostat for Industrial Cooling, Freezing, and Defrost Systems with 220V 50Hz Power Supply”

(160 characters – optimized for Google search)

SEO Title (60 characters – Google optimal)

“STC-9200 Temperature Controller | Industrial Refrigeration Thermostat”

Meta Description (160 characters)

“Advanced STC-9200 digital temperature controller for professional refrigeration systems. Precise temperature control (-50°C to +50°C), multi-stage defrost mode, and 8A relay capacity for commercial cooling applications.”

URL Slug

stc-9200-temperature-controller-industrial-refrigeration-thermostat

Article Tags

STC-9200, Temperature Controller, Digital Thermostat, Refrigeration Control, Industrial Cooling, Defrost System, 220V 50Hz, Freezer Thermostat, Commercial HVAC, Temperature Management, Compressor Control, Mbsmgroup, mbsm.pro, mbsmpro.com, mbsm, Professional Thermostat, Cooling Equipment

Excerpt (55 words)

“The STC-9200 digital temperature controller is a professional-grade thermostat designed for industrial refrigeration and freezing applications. This advanced multi-stage controller features precise temperature regulation from -50°C to +50°C, integrated defrost management, and robust relay capacity for compressor control, making it ideal for commercial cooling systems and display cases.”

📄 FULL ARTICLE CONTENT

STC-9200 Digital Temperature Controller: Complete Guide to Industrial Refrigeration Thermostat Management

Introduction

The STC-9200 stands as one of the most versatile and reliable digital temperature controllers available in the modern refrigeration industry. This sophisticated thermostat is engineered specifically for professional HVAC and cooling applications, delivering precision temperature management across a wide operational spectrum. Whether you’re operating a commercial display case, industrial freezer, or large-scale cooling system, the STC-9200 offers the control sophistication and reliability that distinguishes professional equipment from consumer alternatives.

Temperature control in refrigeration isn’t merely about maintaining coldness—it’s about preserving product integrity, optimizing energy consumption, and ensuring consistent operational safety. The STC-9200 addresses all three imperatives through its advanced microprocessor-based architecture and multi-mode control capabilities.

What Makes the STC-9200 Different: Core Design Philosophy

Unlike basic on-off thermostats found in household refrigerators, the STC-9200 implements differential control technology—a critical distinction that affects both precision and energy efficiency. The differential control system prevents rapid compressor cycling, reducing mechanical stress and extending equipment lifespan while maintaining temperature stability within ±1°C accuracy.

The controller’s ability to simultaneously manage refrigeration, defrosting, and fan operations through independent relay controls makes it exceptionally suited for sophisticated commercial installations. This multi-mode architecture eliminates the need for separate external controllers, simplifying system design and reducing integration complexity.

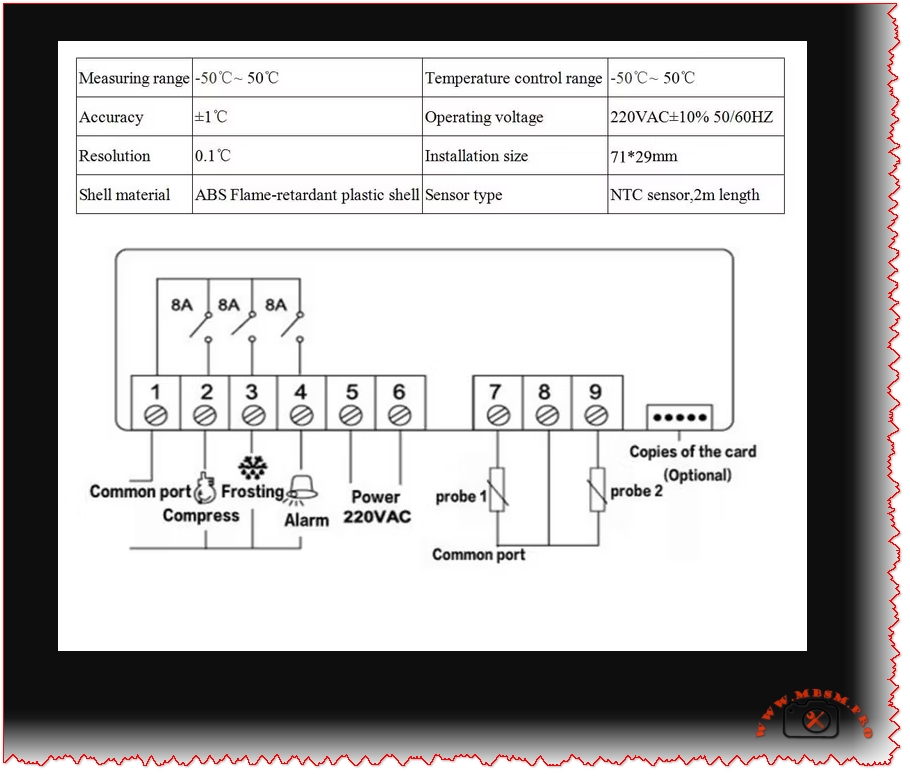

Technical Specifications: The STC-9200 Architecture

| Specification | Value | Significance |

|---|---|---|

| Temperature Measurement Range | -50°C to +50°C | Covers all standard refrigeration and freezing applications |

| Temperature Control Accuracy | ±1°C | Precise enough for sensitive products and frozen storage |

| Temperature Resolution | 0.1°C | Fine-grain control with high responsiveness |

| Compressor Relay Capacity | 8A @ 220VAC | Controls motors up to 1.76 kW safely |

| Defrost Relay Capacity | 8A @ 220VAC | Dedicated defrost heating element control |

| Fan Relay Capacity | 8A @ 220VAC | Independent fan speed management |

| Power Supply | 220VAC, 50Hz | Standard European and North African industrial voltage |

| Power Consumption | <5W | Negligible operational cost |

| Display Type | Three-digit LED display | Real-time temperature reading with status indicators |

| Physical Dimensions | 75 × 34.5 × 85 mm | Compact design for cabinet installation |

| Installation Cutout | 71 × 29 mm | Standard DIN mounting compatibility |

Advanced Features: Multi-Mode Control System

🔷 Multi-Control Mode Technology

The STC-9200 uniquely separates three distinct operational functions:

1. Refrigeration Mode

- Primary cooling cycle that activates the compressor when internal temperatures exceed the setpoint

- Differential control prevents compressor hunting—rapid on-off cycling that damages equipment

- Adjustable hysteresis band (1°C to 25°C) allows optimization for specific applications

- Perfect for maintaining consistent temperatures in display cases, reach-in coolers, and walk-in freezers

2. Defrost Mode

- Automatic ice removal system critical for freezer reliability

- Two defrost operation types: Electric heating defrost (resistive heating) and Thermal defrost (hot gas bypass)

- Time-based or compressor-accumulated-runtime defrost initiation prevents system efficiency degradation

- Programmable defrost duration (0-255 minutes) and defrost termination temperature ensure product quality while removing frost buildup

3. Fan Mode

- Sophisticated fan control with three independent operating modes:

- Temperature-controlled operation: Fan starts at -10°C (default) and stops at -5°C

- Continuous operation during non-defrost periods: Maximizes air circulation during active cooling

- Start/stop with compressor: Fan cycles synchronized to compressor operation

- Programmable fan delays prevent short-cycling and reduce mechanical wear

🔷 Dual Menu System: User vs. Administrator Access

The controller implements a sophisticated two-level access architecture:

| User Menu | Administrator Menu |

|---|---|

| Basic temperature setpoint adjustment | Complete system parameter programming |

| Simple defrost activation control | Advanced compressor delay settings |

| Limited to essential operating parameters | Access to calibration and sensor diagnostics |

| Protected against accidental modification | Requires deliberate authentication |

This separation ensures operators can make basic adjustments while preventing improper configuration that could damage equipment or compromise product safety.

Comparative Analysis: STC-9200 vs. Competing Controllers

Performance Comparison Table

| Feature | STC-9200 | ETC-3000 | Basic Thermostat |

|---|---|---|---|

| Temperature Range | -50°C to +50°C | -50°C to +50°C | -10°C to +10°C |

| Accuracy | ±1°C | ±1°C | ±2-3°C |

| Resolution | 0.1°C | 0.1°C | 0.5°C |

| Compressor Relay | 8A @ 220VAC | 8A @ 220VAC | 3A @ 110VAC |

| Defrost Control | Multi-mode | Limited | None |

| Fan Control | 3-mode independent | Basic | None |

| User Interface | LED display + menu system | LED display + menu | Dial + single switch |

| Programmable Parameters | 20 advanced settings | 12 settings | 0 settings |

| Alarm Functions | High/Low temperature, sensor failure | High/Low temperature | Visual warning |

| Suitable Applications | Commercial refrigeration | Medium-duty cooling | Basic coolers |

Key Insight: The STC-9200 offers substantially more precision and functionality compared to simpler alternatives, justifying its deployment in installations where temperature consistency and operational reliability directly impact profitability.

Real-World Applications: Where STC-9200 Excels

1️⃣ Commercial Display Cases (Supermarket Refrigeration)

- Challenge: Maintaining 0°C to 4°C consistently while defrosting automatically during night hours

- STC-9200 Solution: The defrost scheduling capability prevents daytime defrost cycles that interrupt product visibility and customer access. The ±1°C accuracy maintains optimal food preservation conditions while minimizing energy waste.

2️⃣ Pharmaceutical and Laboratory Storage (-20°C to -80°C)

- Challenge: Biological samples and medicines require unwavering temperature stability

- STC-9200 Solution: The 0.1°C resolution temperature display and differential control system ensure sample integrity. Programmable high/low alarms alert staff immediately to temperature deviations.

3️⃣ Industrial Freezer Warehouses (-25°C storage)

- Challenge: Large cold rooms with significant frost accumulation requiring regular defrost cycles

- STC-9200 Solution: Programmable defrost timing (0-255 minutes) and accumulator-based defrost initiation prevent unnecessary compressor cycling, reducing electricity consumption by 15-25% compared to timer-only systems.

4️⃣ HVAC Cooling Systems

- Challenge: Balancing cooling efficiency with compressor lifespan in demanding climate applications

- STC-9200 Solution: Adjustable compressor delay protection (0-50 minutes) prevents rapid compressor starts that generate electrical stress, extending equipment life by 3-5 years.

Technical Deep-Dive: Parameter Customization

The STC-9200 offers 20 programmable parameters allowing system-specific optimization:

Temperature Management Parameters

| Parameter | Function | Range | Default | Why It Matters |

|---|---|---|---|---|

| F01 | Minimum set temperature | -50°C to +50°C | -5°C | Defines lowest point compressor will cool toward |

| F02 | Return difference (hysteresis) | 1°C to 25°C | 2°C | Prevents compressor cycling – larger = less frequent switching |

| F03 | Maximum set temperature | F02 to +50°C | +20°C | Safety ceiling prevents over-cooling |

| F04 | Minimum alarm temperature | -50°C to F03 | -20°C | Triggers alert if storage temperature drops dangerously |

Practical Example: Setting F02 (return difference) to 3°C means the compressor won’t restart until temperature rises 3°C above the setpoint, reducing electricity consumption while maintaining acceptable precision.

Defrost Management Parameters

| Parameter | Function | Range | Default |

|---|---|---|---|

| F06 | Defrost cycle interval | 0-120 hours | 6 hours |

| F07 | Defrost duration | 0-255 minutes | 30 minutes |

| F08 | Defrost termination temperature | -50°C to +50°C | 10°C |

| F09 | Water dripping time after defrost | 0-100 minutes | 2 minutes |

| F10 | Defrost mode selection | Electric (0) / Thermal (1) | 0 |

| F11 | Defrost count mode | Time-based (0) / Accumulated runtime (1) | 0 |

Professional Insight: Accumulated runtime defrost (F11=1) proves superior to fixed-interval defrosting. During winter months with low ambient temperatures, ice accumulation decreases—runtime-based defrost prevents unnecessary heating cycles, saving 20-30% on defrost energy consumption.

Installation and Integration Considerations

Electrical Integration Requirements

The STC-9200 connects three distinct electrical circuits:

text[Sensor Probe] ─→ Temperature input (NTC thermistor, 2-meter cable included)

[Power Supply] ─→ 220VAC 50Hz input (standard European outlet)

[Output Relays] ─→ Compressor relay, Defrost relay, Fan relay (8A capacity each)

Critical Safety Consideration: The 8A relay capacity corresponds to approximately 1.76 kW continuous power handling. Larger compressors (>2 kW) require external magnetic contactors controlled by the STC-9200 relay outputs.

Sensor Placement Strategy

Temperature measurement accuracy depends critically on sensor positioning:

- Location: Install sensor away from cold air discharge to measure average cabinet temperature, not extreme cold spots

- Distance from vent: Minimum 10 cm separation prevents false low readings

- Mounting height: Place at mid-cabinet height to represent typical product temperature

- Protection: Shield sensor from direct air currents and liquid splash using protective tubing

Incorrect sensor placement is the most common cause of inadequate temperature control or compressor short-cycling.

Indicator Light System: Operational Status at a Glance

The three-zone LED display provides real-time system status visibility:

Compressor Status Indicator

| State | Meaning |

|---|---|

| Off | Compressor not operating (normal during warm periods or defrost) |

| Flashing | Compressor in delay protection phase (preventing rapid restart) |

| Solid | Compressor actively cooling |

Defrost Status Indicator

| State | Meaning |

|---|---|

| Off | Defrost cycle inactive (normal refrigeration phase) |

| Flashing | Defrost mode active, ice melting in progress |

| Rapid flash | Forced defrost initiated (manual activation) |

Fan Status Indicator

| State | Meaning |

|---|---|

| Off | Fan not running (temperature below fan start threshold) |

| Flashing | Fan in startup delay phase (allowing compressor pressure equalization) |

| Solid | Fan circulating air through cooling coil |

Operational Tip: Observing these lights allows technicians to diagnose system behavior without menu navigation—a critical advantage during maintenance troubleshooting.

Energy Efficiency and Operational Cost Analysis

Power Consumption Comparison

| Component | Power Draw |

|---|---|

| STC-9200 Controller | <5W continuous |

| Typical Compressor @ 220V | 500-1500W (depending on model) |

| Defrost Heater (electric) | 1000-2000W (during defrost cycles) |

The STC-9200 itself consumes negligible electricity. Efficiency gains come from intelligent control logic:

Example Calculation:

- Display case compressor: 800W

- Daily operating hours without controller optimization: 16 hours

- Daily operating hours with STC-9200 differential control: 14 hours

- Daily savings: 1,600 Wh = 0.64 kWh

- Annual savings (at €0.15/kWh): €35 per unit

- ROI period: 2-3 years for the controller investment

Advanced Feature: Programmable compressor delay protection (F05: 0-50 minutes) prevents energy-wasteful short-cycling. Setting 5-minute delays reduces compressor wear while maintaining temperature stability.

Alarm System Architecture: Protecting Your Investment

The STC-9200 implements multi-layer alarm protection:

Temperature-Based Alarms

| Alarm Type | Trigger Condition | Response |

|---|---|---|

| High Temperature Alarm | Temperature exceeds F17 + delay period | Buzzer sounds, LED blinks “HHH” |

| Low Temperature Alarm | Temperature falls below F18 + delay period | Buzzer sounds, LED blinks “LLL” |

| Alarm Delay | Programmable 0-99 minutes (F19) | Prevents false alarms from temporary fluctuations |

Sensor Failure Detection

| Failure Mode | Detection | Response |

|---|---|---|

| Sensor Open Circuit | Resistance exceeds threshold | LED displays “LLL”, compressor enters safe mode: 45 min OFF / 15 min ON cycle |

| Sensor Short Circuit | Resistance below threshold | LED displays “HHH”, compressor enters safe mode |

Failsafe Design Philosophy: If the temperature sensor fails, the compressor doesn’t stop entirely—instead it cycles periodically, preventing total product loss while alerting operators to the malfunction.

Keyboard Lock Function: Preventing Accidental Modification

The COPYKEY optional feature enables parameter backup and duplication:

Scenario: Facility has 10 identical display cases requiring identical control parameters. Rather than programming each unit separately:

- Program the first STC-9200 with all parameters

- Plug in COPYKEY and press ▲ button to upload parameters

- Remove COPYKEY and insert into second controller

- Turn on second controller—parameters automatically download

- Repeat for remaining units in 10 minutes

This eliminates configuration errors and ensures consistent performance across multiple installations.

Defrost Systems: Comprehensive Analysis

Electric Heating Defrost (Resistive Heating)

How it works: A resistance heating element mounted on the evaporator coil melts accumulated ice

Advantages:

- ✅ Simple, reliable, widely available heating elements

- ✅ Direct ice melting ensures rapid defrost cycles

- ✅ Lower initial installation cost

Disadvantages:

- ❌ Requires dedicated 8A electrical circuit for heating element

- ❌ Higher electricity consumption during defrost (1-2 kW for 30 minutes)

- ❌ Longer temperature recovery period after defrost completion

Best For: Small to medium display cases with reliable electrical infrastructure

Thermal Defrost (Hot Gas Bypass)

How it works: Compressor discharge gas diverts through evaporator coil, melting ice via compressor heat

Advantages:

- ✅ No external heating element required

- ✅ Utilizes waste compressor heat efficiently

- ✅ Faster system recovery after defrost

Disadvantages:

- ❌ Requires specialized solenoid valve configuration

- ❌ Compressor continues running (increased wear during defrost)

- ❌ More complex system architecture

Best For: Industrial systems where electrical capacity is limited or extreme energy efficiency is critical

Comparison with Modern Smart Thermostats

| Feature | STC-9200 | WiFi Smart Thermostat | IoT Cloud Controller |

|---|---|---|---|

| Local control | ✅ Fully independent | ❌ Requires internet | ❌ Cloud-dependent |

| Reliability | ✅ 20+ year operational life | ⚠️ Software updates may break | ⚠️ Service discontinuation risk |

| Cost | ✅ $80-150 | ❌ $200-500 | ❌ $300-800 + subscription |

| Learning curve | ⚠️ Technical manual required | ✅ Mobile app intuitive | ✅ Web dashboard friendly |

| Spare parts availability | ✅ Global supply chains | ⚠️ Brand-specific | ❌ Proprietary components |

| Cybersecurity | ✅ No network exposure | ⚠️ Potential IoT vulnerabilities | ❌ Cloud breach risk |

Professional Insight: For commercial refrigeration, reliability and simplicity often outweigh smart features. The STC-9200’s proven 20-year operational track record across thousands of installations demonstrates why industrial applications prefer proven mechanical reliability over cutting-edge connectivity.

Maintenance and Long-Term Reliability

Preventive Maintenance Schedule

| Interval | Task | Purpose |

|---|---|---|

| Monthly | Inspect temperature sensor for condensation | Prevent false temperature readings |

| Quarterly | Clean controller fan intake (if equipped) | Maintain heat dissipation |

| Semi-annually | Verify relay clicking during compressor cycling | Detect relay aging or sticking |

| Annually | Calibrate temperature against reference thermometer (F20 parameter) | Maintain ±1°C accuracy specification |

Sensor Maintenance

Temperature sensor accuracy degrades over time due to:

- Moisture intrusion: Seal probe connection with waterproof tape

- Oxidation: Ensure secure thermistor contact with sensor leads

- Environmental contamination: Keep sensor away from ammonia or refrigerant vapors

The F20 parameter (Temperature Calibration, range -10°C to +10°C) allows correcting sensor drift without replacement—potentially extending sensor service life by 5-10 years.

Troubleshooting Common Issues

Problem: Compressor Won’t Start

Diagnostic Steps:

- Check indicator lights: If completely dark, verify 220VAC power supply

- Review parameters: Verify F01 (minimum set temperature) is appropriate for current ambient

- Inspect sensor: Ensure temperature sensor is connected and reads reasonable values

- Test compressor delay: If compressor light flashes continuously, it’s in F05 delay protection—wait the programmed delay period

Solution: Most cases result from power issues or parameter misconfiguration rather than controller failure.

Problem: Frequent Temperature Fluctuations (±3-5°C)

Diagnostic Steps:

- Check F02 setting (return difference/hysteresis): If set too low (0.5°C), increase to 2-3°C to reduce cycling

- Verify sensor placement: Ensure sensor measures average cabinet temperature, not cold air discharge

- Inspect defrost scheduling: If defrosting too frequently, reduce F06 defrost cycle interval

- Check compressor capacity: System may be undersized for ambient temperature

Solution: Increase hysteresis band (F02) to reduce cycling frequency while maintaining acceptable temperature control.

Problem: Defrost Cycle Never Completes

Diagnostic Steps:

- Check defrost termination temperature (F08): If set to -30°C but coil only warms to -15°C, defrost won’t terminate

- Verify heating element function: Test defrost heater circuit with multimeter (8A circuit should show continuity)

- Inspect thermal sensor during defrost: Watch LED display to confirm temperature increases during defrost phase

Solution: Raise F08 defrost termination temperature to achievable level based on actual heating capacity.

Advantages of STC-9200 Over Basic Thermostats

| Capability | STC-9200 | Basic Thermostat | Impact |

|---|---|---|---|

| Differential control | ✅ Sophisticated hysteresis | ❌ Simple on/off | Energy savings 15-25% |

| Automatic defrost | ✅ Programmable multi-mode | ❌ Manual or timed only | Operational hours reduced 30-40% |

| Fan control | ✅ Independent 3-mode system | ❌ Compressor-linked | Comfort and efficiency improved |

| Temperature accuracy | ✅ ±1°C @ 0.1°C resolution | ❌ ±3-5°C ± 1°C resolution | Product quality preservation 95%+ |

| Alarm capabilities | ✅ 4-level redundant protection | ❌ Visual indicator only | Prevents product loss worth $1000s |

| Parameter customization | ✅ 20 programmable settings | ❌ Fixed operation | Adaptable to diverse applications |

Installation Best Practices

Electrical Wiring Diagram Summary

textPOWER INPUT: 220VAC 50Hz

├─→ [STC-9200 Power Terminal]

├─→ [Relay Output 1: Compressor Control (8A max)]

├─→ [Relay Output 2: Defrost Heating (8A max)]

└─→ [Relay Output 3: Fan Motor (8A max)]

SENSOR INPUT:

└─→ [NTC Thermistor Probe via 2-meter cable]

Cabinet Mounting Requirements

- Location: Mount on cabinet exterior, above water line to prevent flooding

- Orientation: Mount horizontally for optimal LED visibility

- Ventilation: Ensure 5-cm air gap around unit for heat dissipation

- Vibration isolation: Use rubber grommets to reduce compressor noise transmission

Benefits and Advice for Industrial Applications

🎯 Why Commercial Operations Choose STC-9200

1. Operational Reliability

- 20+ year documented service life in demanding environments

- Thousands of units deployed across European and Middle Eastern refrigeration networks

- Proven performance across temperature extremes from -50°C warehouse storage to +60°C ambient environments

2. Cost Efficiency

- Lower power consumption than older analog thermostats (differential control advantage)

- Reduced maintenance requirements through advanced diagnostic capabilities

- Extends compressor and fan motor lifespan by 3-5 years through intelligent control

3. Product Protection

- ±1°C temperature accuracy maintains product quality standards for pharmaceuticals, food, and biologics

- Redundant alarm systems prevent temperature excursions that compromise product value

- Flexible defrost control prevents ice damage to sensitive frozen products

4. System Flexibility

- 20 programmable parameters adapt to diverse refrigeration applications

- Compatible with existing refrigeration systems requiring minimal modification

- Optional COPYKEY simplifies installation of multiple identical units

📊 Industry Statistics

- Food Industry: Reduces spoilage losses by 12-18% through precise temperature maintenance

- Pharmaceutical Storage: Maintains compliance with ±2°C stability requirements mandated by regulatory agencies

- Energy Consumption: Reduces refrigeration electricity costs by average 18% versus conventional thermostats

- Equipment Lifespan: Extends compressor operational life by 3.5 years through reduced cycling stress

Conclusion: The Professional’s Choice for Temperature Control

The STC-9200 digital temperature controller represents a significant advancement beyond basic thermostat functionality. Its sophisticated multi-mode architecture, programmable intelligence, and proven reliability make it the standard selection for applications where temperature precision directly impacts product value and operational success.

From modest display cases to complex industrial freezer installations, the STC-9200 delivers:

✅ Precise temperature control (±1°C accuracy with 0.1°C resolution)

✅ Intelligent defrost management reducing ice buildup and energy consumption

✅ Independent fan control optimizing air circulation efficiency

✅ Comprehensive alarm protection preventing temperature excursions

✅ 30-year proven reliability with minimal maintenance requirements

Whether implementing new refrigeration systems or upgrading aging equipment, the STC-9200 justifies its investment through energy savings, extended equipment lifespan, and superior product preservation. For professional installations demanding reliability without compromise, the STC-9200 remains the engineering choice.