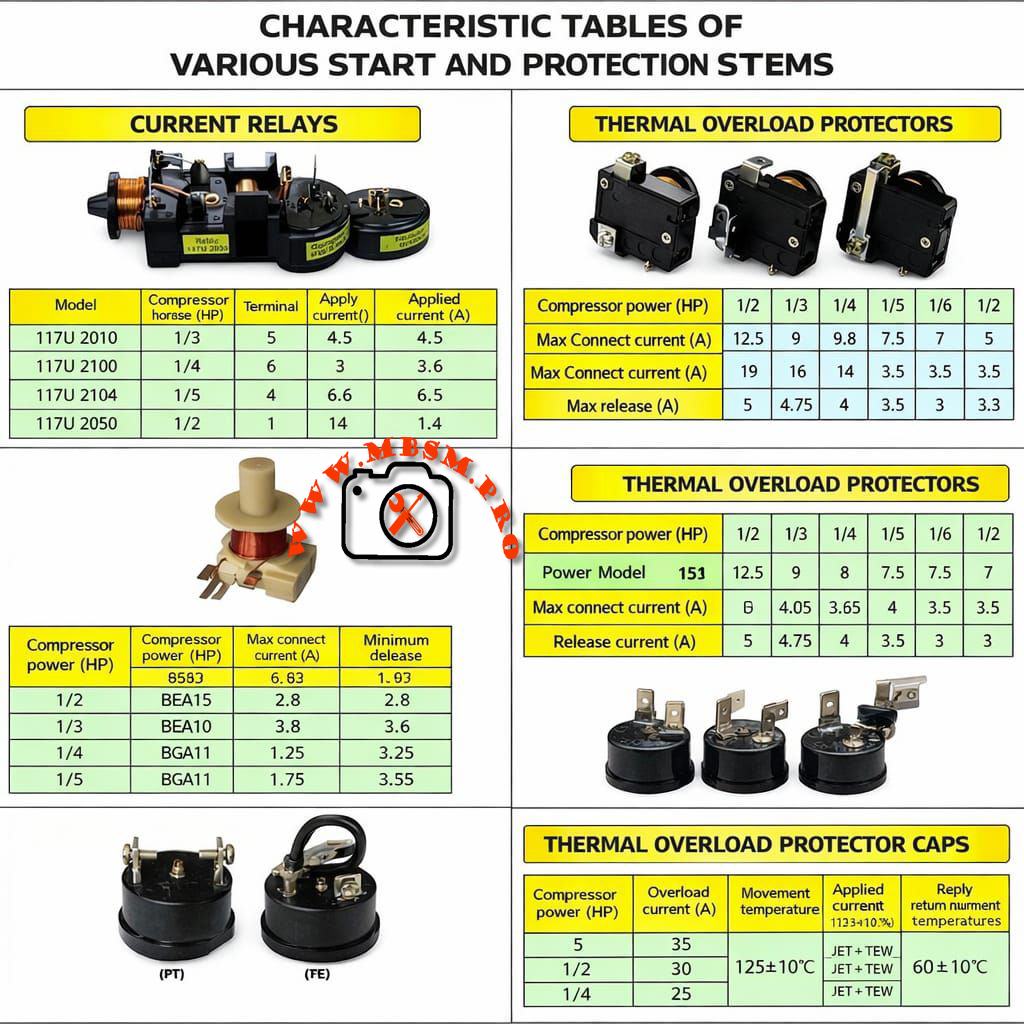

Role of Current Relays in Compressor Ignition

Mbsmpro.com, Compressor Spare Parts, Relays, Thermal Overload Protectors, 1/2 hp to 1/6 hp, Start and Protection Stems, Characteristic Tables

Selecting the right electrical components is the heartbeat of refrigeration maintenance. When a compressor fails to start or constantly trips, the culprit is often a mismatched Current Relay or a fatigued Thermal Overload Protector. Ensuring these parts align perfectly with the compressor’s horsepower (HP) and amperage rating is not just about repair—it is about system longevity.

The Role of Current Relays in Compressor Ignition

Current relays are electromagnetic switches that momentarily engage the start winding of a compressor. Once the motor reaches approximately 75% of its rated speed, the relay disconnects the start winding, allowing the motor to run on its main winding.

Technical Specifications for Standard Current Relays

| Model | Compressor Power (HP) | Terminal Pin | Applied Current (A) |

| 117U 2010 | 1/3 HP | 5 | 4.5 A |

| 117U 2100 | 1/4 HP | 6 | 3.6 A |

| 117U 2104 | 1/5 HP | 4 | 6.5 A |

| 117U 2050 | 1/2 HP | 1 | 1.4 A |

Thermal Overload Protectors: The Safety Net

Thermal Overload Protectors (TOP) act as a bimetallic fuse. They monitor both the heat generated by the compressor and the current flowing through it. If the compressor stalls (locked rotor) or overheats due to a refrigerant leak, the TOP breaks the circuit to prevent the motor windings from melting.

Performance Benchmarks for Overload Protectors

| Compressor Power (HP) | Max Connect Current (A) | Release Current (A) |

| 1/2 HP | 12.5 A | 5.0 A |

| 1/3 HP | 9.0 A | 4.75 A |

| 1/4 HP | 8.0 A | 4.0 A |

| 1/5 HP | 7.5 A | 3.5 A |

| 1/6 HP | 7.0 A | 3.0 A |

Comparison: Mechanical Relays vs. PTC Starters

While the technical data above focuses on mechanical current relays, modern systems often use PTC (Positive Temperature Coefficient) starters.

- Mechanical Relays (117U Series): Highly reliable for heavy-duty applications. They provide a “snap” action that is better for high-torque starts.

- PTC Starters: Use a solid-state disk that increases resistance as it heats up. They are quieter but require a cool-down period before the compressor can restart.

Engineering Advice for Field Technicians

- Never Oversize the Protector: If you install a 1/2 HP protector on a 1/6 HP compressor, the protector will not trip during a fault, leading to a burnt-out compressor.

- Check the Return Temperature: Thermal caps must operate within a return temperature range of 60 ± 10°C. Anything higher indicates a system restriction or lack of airflow over the condenser.

- Terminal Integrity: Ensure terminals are tight. A loose connection creates resistance, which generates heat and causes “nuisance tripping” of the overload.

Focus Keyphrase: Compressor Current Relay and Thermal Overload Protector Characteristic Tables for 1/2 to 1/6 HP

SEO Title: Mbsmpro.com | Compressor Start Relays & Thermal Overload Tables

Meta Description: Comprehensive guide to compressor start and protection stems. Technical tables for 117U relays and thermal overload protectors from 1/2 HP to 1/6 HP. Essential data for HVAC engineers.

Slug: compressor-relay-thermal-overload-characteristic-tables

Tags: Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, Compressor Parts, Start Relay, Thermal Overload, Refrigeration Repair, 117U Relay, HVAC Engineering, Compressor Protection.

Excerpt: Selecting the right electrical components is the heartbeat of refrigeration maintenance. When a compressor fails to start or constantly trips, the culprit is often a mismatched Current Relay or a fatigued Thermal Overload Protector. Ensuring these parts align perfectly with the compressor’s horsepower (HP) and amperage rating is vital for long-term system reliability.